In the heart of the Taunton Vale, you will find a magical little den that is surrounded by acres of farm land, and in that little den you will find a master cider maker, crafting traditional Somerset cider.

From the beginning our story behind Bray’s Cider.

In 1918 Abraham Bray, a Devon farmer, made his own cider, from his own orchard, for his own farm workers in order to top up their weekly wages. This was a common method of payment for farm workers at this time.

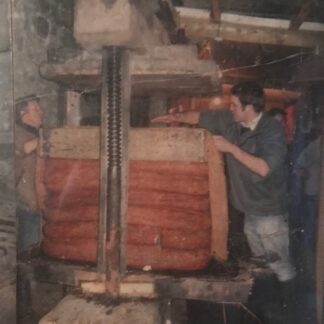

Abraham made his cider using a traditional rack and cloth method. This consisted of the apple pomace (pulp) being formed into cheeses (layers of pomace folded into cloths with wooden racks in between each cloth) the cheese is then pressed by applying pressure to squeeze out the apple juice. The juice is then stored in oak barrels for around 7 months until the fermentation process has finished resulting in cider.

A statement from Samuel Kekewich, Tory M.P. for South Devon 1850:

‘Cider is the most wholesome beverage that a labourer can use… The labourer born in this county and used to cider from his earliest years will not drink beer. Indeed, it makes them heavy, sleepy and stupid, whereas cider has a contrary effect. … It is quite true that they often drink too much, but that is not the fault of the farmer, but of the men, who will not work in mowing, reaping or turnip hoeing, unless they have as much as they like to ask for.

As to the payment of wages in cider, you are mistaken in thinking that the farmers insist on this to get rid of their bad cider. The labourers will not have it … It is a mistake to suppose that if the labourer were paid 10s instead of 8s 6d in money and 1s 6d in cider, that the 1s 6d would go in bread and meat. If he was deprived of cider during the hours of labour when he requires it, he would go to the cider shop, one of the worst places of resort, where all the worst people congregate. …

I make no cider, and do not purchase it for my labourers, and therefore I give my labourers 11s per week, but I am sure they would prefer cider.’

As time progressed and as history suggests this method of payment was becoming less favourable with workers. Due to the fact that they were required to use more machinery than before and laws brought in to propose that workers were no longer allowed to be paid in cider.

In 1949 the next generation of Bray’s, Geoffrey Bray had taken over the cider making process, using mixed variety apples and using the same rack and cloth methods. However, due to the lack of demand for his workers to be paid in cider, he sold his delectable home produce to the local pubs in Devon.

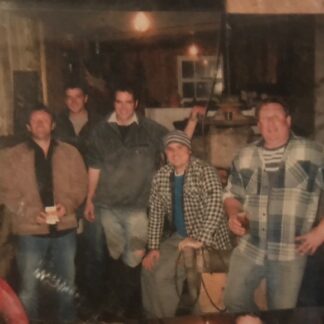

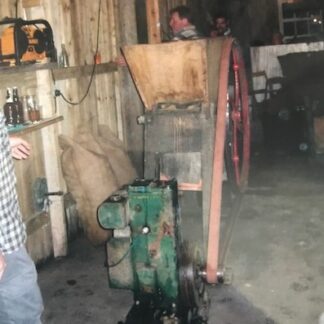

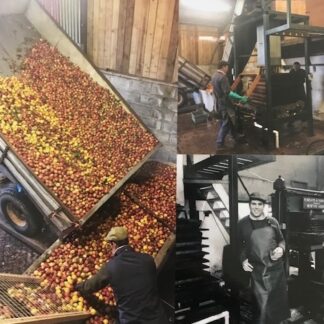

As the Brays left Devon for Somerset, milking cows took over from cider production. It wasn’t until 2005 when Adam Bray decided to revisit the cider heritage of his Grandfather and Great Grandfather, by reinstating his own ‘Cider Shed’ as a memorial to his predecessors that cider was produced by the Bray family again. Over time equipment was acquired and friends gathered in order to bring back to life the traditional cider making process.

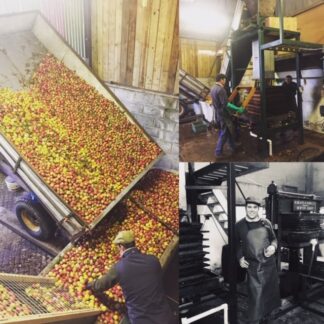

In the months of October and November Adam and friends gathered to make their own cider in the same traditional way. Over the years they collected numerous apples, from numerous orchards and made numerous gallons of cider, it came to a point in 2012 it was apparent they had more cider than they could drink on their own.

Having been blessed to be in the perfect location for a passing trade – the A358 the busiest road in Somerset, and it being June, the start of the festival season, what better time to erect some cider signs and start selling some proper cider.

As the cider sold out an increase in production was required, in order to meet this demand new equipment was necessary (and when we say new we mean a 60 year old press instead of a 200 hundred year old press) and a larger premises was required (still on the farm just a bigger shed). The quantity of apple juice that we were pressing in a week we can now press in just 2 hours – with the help of hydraulics instead of muscle power. We are still using the same traditional rack and cloth principles, storage and fermenting processes.

Having perfected the flavour and blend of our dry and sweet farmhouse cider, lead us to creating a sparkling cider, appealing to a wider market helping to grow our brand throughout the UK. We now have an online shop, as well as a cider shop on the farm. We hope in the future to reach pubs and festivals with our proper Somerset cider.

Our cider is made with a 100% apple juice and as naturally and traditionally as possible. Our aim is to keep the traditional art of cider making alive, we make our cider with friends and encourage everyone to be part of and understand the art of an age old tradition.